The PrintFoam Story

The PrintFoam story starts at MIT.

MIT research specialist Matthew Pearlson spent his career in alternative fuels and renewable energy. His research led him into entrepreneurship in green jet fuels, as well as project development in wind, solar, and biofuels around North America.

Once Matthew heard a talk from Amory Lovins of “Reinventing Fire” fame, he developed a new obsession: lightweighting garbage trucks. This vision was far-reaching, offering these vehicles – so ubiquitous especially throughout every street in the US – a new design that could make them quieter, more efficient, and ultimately more sustainable on a huge scale. Lightweighting something so commonplace could have a massive impact on our city streets.

This idea continued to mature and took a new shape as Matthew sought ways to make an impact in his lifetime when it comes to a more sustainable world. How could sustainability be achieved through lightweighting, through materials science? Controlled foam production! Thus was born The Foam Printing Project in 2016.

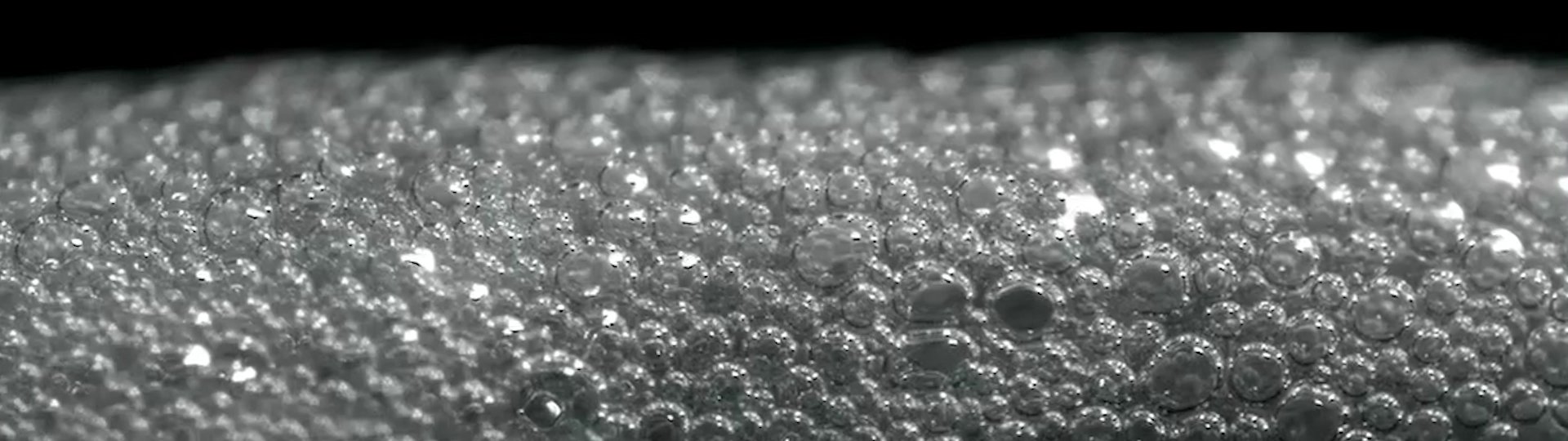

Bubbles.

True 3D printed foam has a very straightforward characteristic: bubbles.

Matthew filed his first patent, “Additive Manufacturing Using Foaming Radiation-Curable Resin”, soon after.

A highly sought-after MIT Sandbox Innovation Fund award in 2017 offered the initial funding and space for The Foam Printing Project to begin prototyping in the lab. Data obtained from these early results led to the next award, as 2018 saw the RadTech RadLaunch award recognize the potential impact for 3D printing lightweight, low-cost foam.

The next year proved a point of acceleration as in 2019 a Small Business Innovation Research (SBIR) Phase I project award offered a larger budget to explore the possibilities. Rigorous customer discovery opened up market awareness in footwear, automotive, aerospace, medical, and R&D segments. Through these conversations and early R&D contracts, Matthew realized retrofitting existing 3D printers wouldn’t offer the speed that real-world customers needed.

This set the table for the big question: How do you take the surface finish and dimensional accuracy of SLA/DLP vat photopolymerization and scale it to large sizes without sacrificing speed or resolution?

Typical tradeoffs for size, speed, and resolution are along the lines of achieving 2x build volume leads to 4x the build time at the same resolution. Matthew set an ambitious target to print foam the size of a standard sheet of plywood (4’ x 8’ x 0.5”) in 15 minutes. That's micro-featured structures across something the size of a door printed in less time than it takes to bake a pizza.

By 2020, the first major contracts started rolling in. Next-generation acoustic panels created for the construction project showed 10x superiority to conventional insulation. Further investigation of industrial installations in the energy infrastructure sector led to a pivot from consumer goods to a new focus: clean tech.

Drawing back to the idea’s roots in lightweighting for sustainability, PrintFoam began a pivot to examine the wider environmental implications of 3D printed foam.

Then COVID-19 hit.

PrintFoam relocated from a Boston HQ to the Midwest. The current home base of operations, in Wisconsin, places R&D nearby economic centers like Milwaukee and Chicago with room to grow. During early pandemic lockdowns, when he couldn’t access his regular lab and equipment, Matthew rented a temporary space to begin work on next-generation foam printing hardware to begin turning toward the scale and speed goals.

In 2022, the next growth stages coalesced with a SBIRAdvance award from state of Wisconsin, a new patent filing for the next-generation hardware, and, vitally, a brilliant CTO coming onboard.

The expanded PrintFoam team could drive forward proofs-of-concept to validate claims of process on a small-scale development machine to prove out what their math showed: high-speed, large-scale vat photopolymerization with bubbles is possible.

These proof points have offered additional credibility and intrigue. An MOU signed for an R&D and pilot project is moving PrintFoam toward its aim of the first big project worth $100+ million per year for 10 years.

So fundraising kicked off in earnest. Talks with investors have shown significant interest in the potential for PrintFoam, and we hope to announce some exciting news in the next few months!

As 2023 kicks off, PrintFoam will be focused on advances in hardware and materials to deliver the next generation of 3D printed foam. Expansions to the team and customer base are in sight.