PrintFoam… 3D prints foam!

Our team leverages expertise in materials science and additive manufacturing to enable 3D printed foam parts.

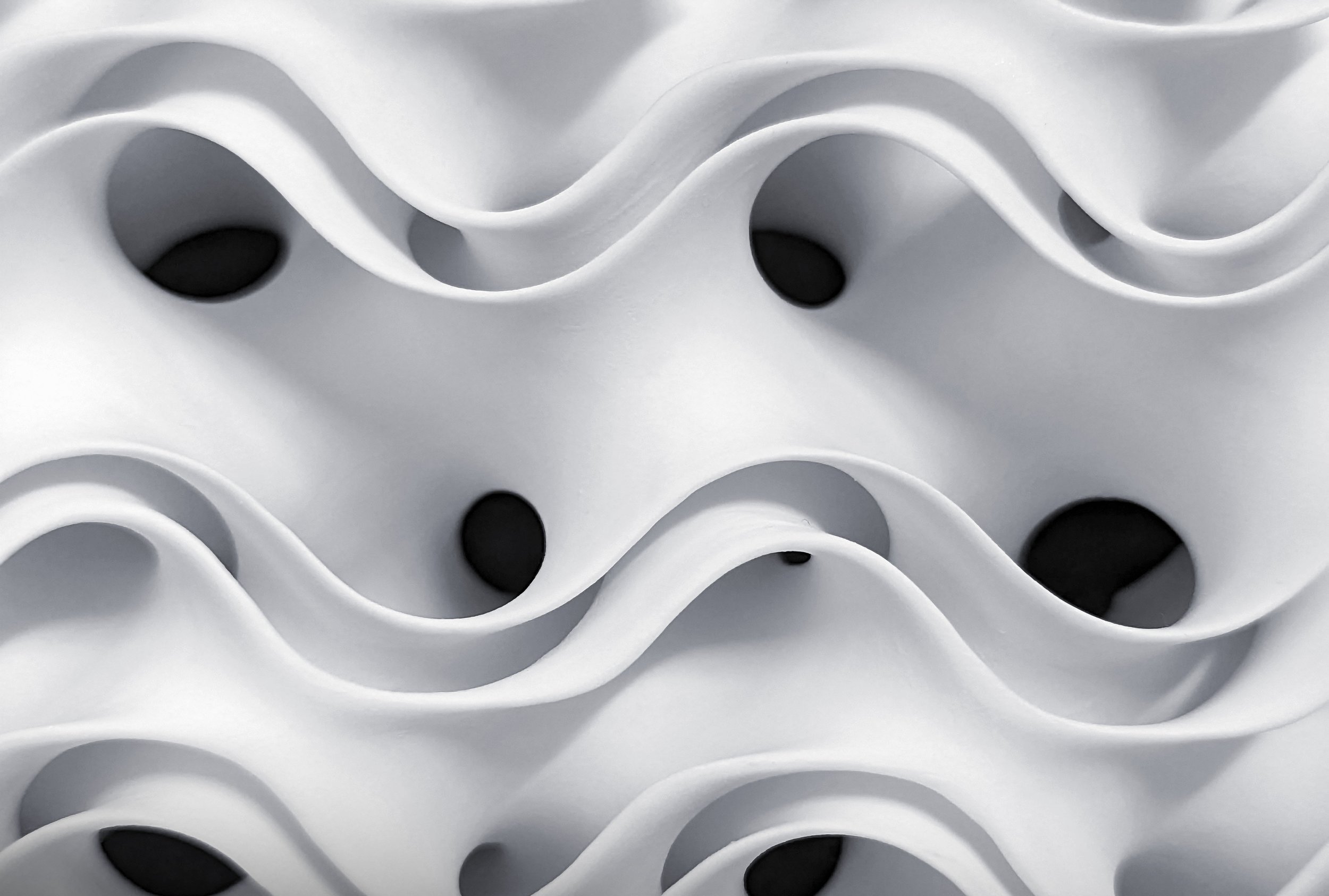

Manufacturers of products traditionally constructed with foam (helmets, bike seats, shoe soles) have been looking to leverage the advantages of additive manufacturing (on-demand production, increased design complexity, consolidation of parts, stability of supply chain, etc.) – but 3D printed lattices have not been able to replicate the innate material performance of foams.

PrintFoam has patented hardware and materials solutions which enable the high-throughput 3D printing of large foam objects.

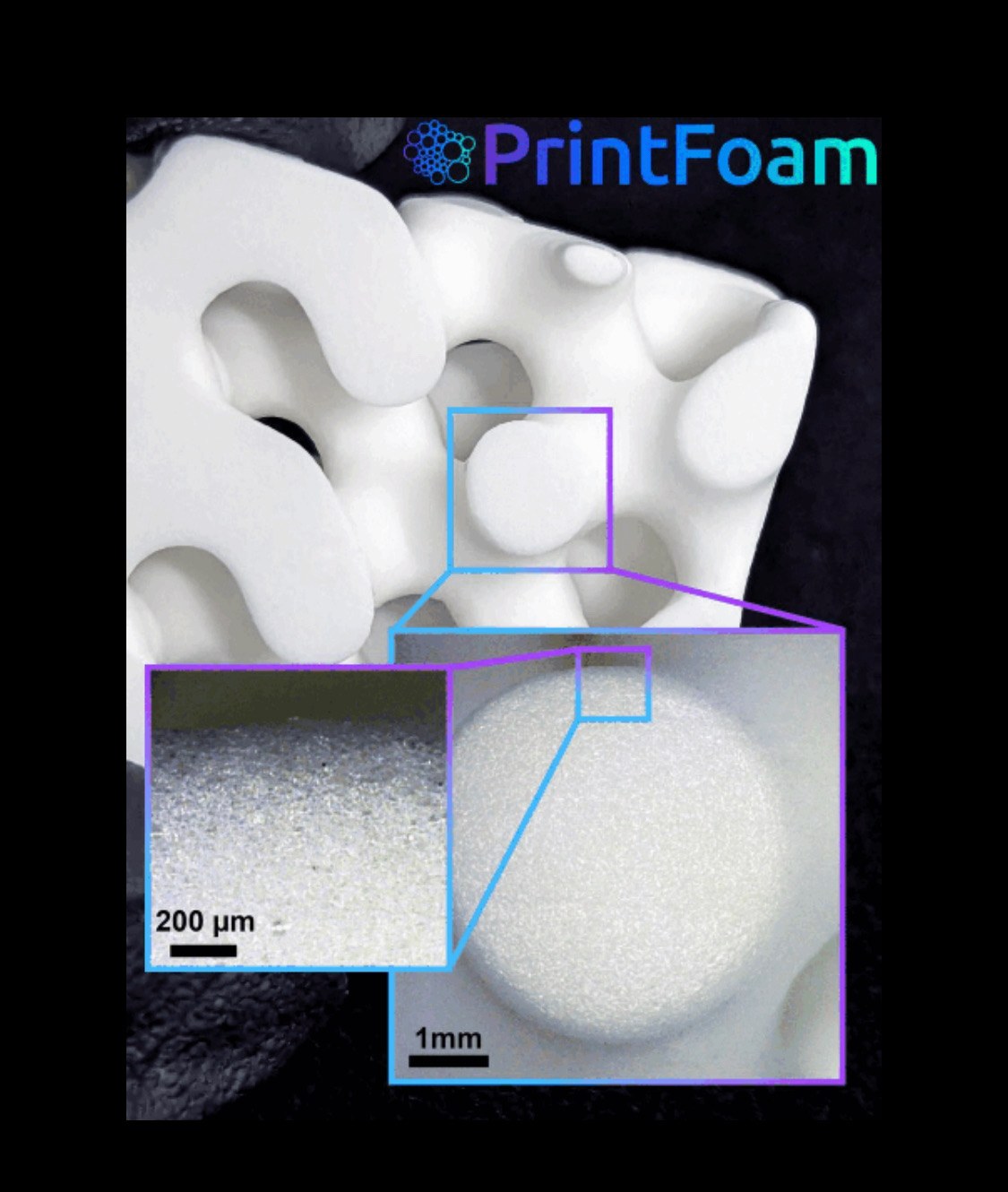

We’re not talking lattices for lightweighting; we’re talking real foam, complete with bubbles.

Real Foam. 3D Printed.

PrintFoam offers a range of photoresins which can vary the matrix properties of foam porosity.

Because our hardware enables the rapid 3D printing of high-viscosity resins, material performance is superior to most other photopolymer 3D printing technologies on the market.

Materials filled with ceramic, metal, glass/polymer fibers and particles can be designed to produce tuned EM/RF, thermal, acoustical, and mechanical performance not seen in other materials.

-

CEO & Co-Founder

Matthew Pearlson is the Chief Executive Officer (CEO) and Co-Founder of PrintFoam, having ideated the technology while at MIT in 2016.

Matthew holds a BS in Chemical Engineering from UMass Amherst, and a master’s in engineering systems from MIT. His focus at MIT’s Laboratory for Aviation and the Environment (LAE) at MIT’s Department of Aeronautics and Astronautics led to development of technical and economic production (“techno-economics”) of alternative jet fuels using cash-flow analysis.

Matthew has also developed deep expertise in additive manufacturing of lightweight structures using novel 3D printing technologies; software design and testing; petroleum refining; alternative fuels production; utility-scale renewable energy systems; multi-modal transportation optimization; and digitization.

-

CTO & Co-Founder

Dr. David Walker is the Chief Technology Officer (CTO) & Co-Founder of PrintFoam, as well as the Executive Chairperson of the Photopolymer Additive Manufacturing Alliance (PAMA).

David graduated with his PhD from Northwestern University in 2014, during which he studied nano-scale materials. During his doctoral studies he received a Feynman award from the Foresight Institute, an international thinktank, for his contributions to the field of nanotechnology. Following his graduation, David was an Adjunct Professor in Chemical and Biological Engineering at Northwestern University teaching graduate courses in thermodynamics. His ongoing research and technical innovations in robotic driven automated chemistry for pharmaceutical applications would eventually bring him to the field of additive manufacturing in 2015 and to co-found Azul 3D in 2017. In 2019, David published a seminal work, in the journal Science, which set a new throughput record for the field of vat photopolymerization printing. David would go on to lead Azul 3D as the President, CTO, & Co-Founder growing the company from zero to 35+ FTEs until his exit in 2022.

David additionally serves on the board of RadTech America (an industry organization for UV/EB thermoset materials), is an active participant within ASTM F42, serves on the advisory board of multiple 3D printing companies, and writes about technical and business challenges relating to polymer-based additive manufacturing technologies.

David joined PrintFoam in 2022 as CTO & Co-Founder. His contributions have rapidly scaled the company’s capabilities in terms of material formulations, material handling, and application development.

PrintFoam Intern Alumni

-

Kevin

UW-Milwaukee

Electrical and Computer Science Engineering

-

Ally

Marquette Engineering

Biomechanical Engineering

-

Grace

University of Virginia

Mechanical Engineering

-

Abraham

Marquette University

Electrical Engineering

Investments & Awards